Pocket Doors

Pocket doors: a mini-guide for choosing the right sliding pocket door

How to understand the difference between the different models (single, double, classic or flush pocket door), to correctly calculate the size of the door opening and the overall dimensions. How to choose and identify the type of frame on the basis of the door, the opening and walls.

The box contains detailed information on each topic.

Understanding sliding pocket doors from A to Z

What is the difference between an exposed sliding door and a sliding pocket door?

Unlike traditional hinged doors, sliding pocket doors allow to regain the space usually taken up by the radius of the door swinging and help create a wider and more welcoming environment, offering greater furnishing options. Removing the hinged doors, the home wins back more space that can be essential for rooms which are small in size, benefiting of a more refined interior decoration.

There are two types of sliding doors:

- barn doors

- sliding pocket doors

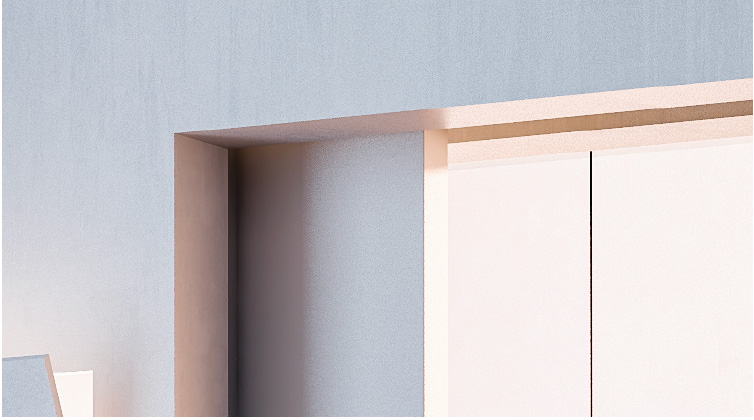

In the former case, the door opens by sliding alongside the wall, while in the latter case the door opens by sliding inside it, running into a system commonly known as the ‘counterframe’. The counterframe of a sliding pocket door is a metal pocket that allows the door to slide inside the wall concealing from sight. Both solutions solve a space problem but, compared to the exposed sliding door version, the sliding pocket door frees the space on the wall where the door slides, opening up to greater furnishing possibilities. Depending on the type of frame adopted, several different opening solutions can be obtained.

A sliding pocket door system: what it is and how it works

The details of the metal structure specially designed for both solid wall and stud wall

The counterframe for a sliding pocket door is a metal structure enabling the door to disappear inside a wall (either solid or stud wall). The frame is made up of a pocket that replace the wall section where the door is going to enter, a sliding system (track and runners) located in the upper part that allows the door panel to slide and a vertical metal door stop that accomodate the closing door.

To qualify as a premium-quality product, the frame necessarily needs to comply with specific reliability and durability requirements.

Sturdiness: the frame must be as sturdy as the wall and it has to be inspectable at any time to allow its maintenance without knocking the wall down.

Smooth and fluid sliding movement of the door: the runners and the track ensure the maximum smoothness to the sliding movement and can be easily replaced if they get damaged.

Guarantee of a steady and indeformable internal passage, resistant to lateral pressures, with no deflection of the pocket's metal sheet and, thus, no risk of hindering or damaging the door.

Guarantee of a crack-resistant plaster finish: being an integral part of the wall, the counterframe does not alter the appearance and consistency of the wall.

Easy installation and maintenance: a frame that is easy to assemble and to install even by non-expert personnel guarantees and safeguards the product over time. This is possible thanks to a maintenance free track fully extractable which enables to retrofit accessories after the installation with no need of masonry.

Always aiming at the best possible quality, in 30+ years of research ECLISSE has developed a product boasting the following features:

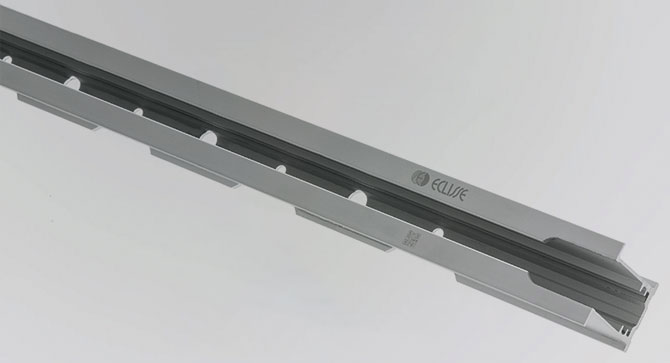

Extractable track

No worries

With this solution it is possible to replace any parts subject to wear, apply accessories and adjust the internal door stop mechanism.

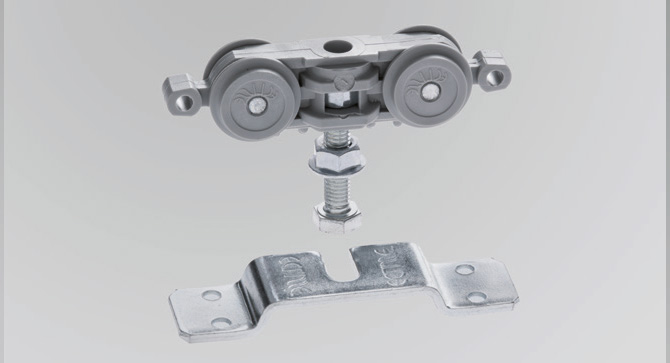

Runners with ball bearings

Smoothness and fluidity

The sliding runners are certified to guarantee durability, smooth movements and a silent sliding. The standard load-bearing capacity is 220 lbs per pair, 330 lbs on request.

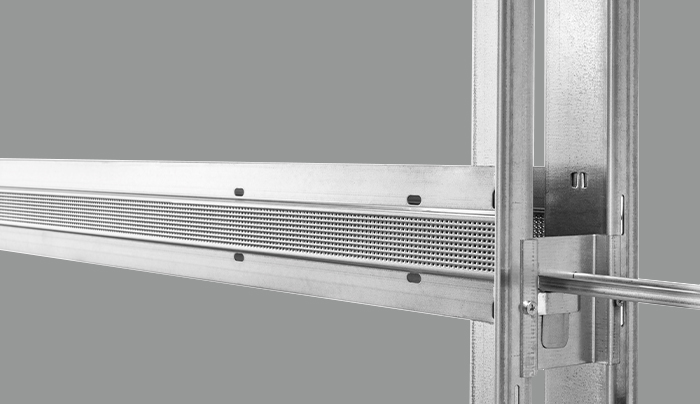

Alignment bar

Always perfectly centered

This is a special galvanized metal sheet profile that facilitates the installation by aligning the counterframe with the metal door post.

Calculating the dimensions of a sliding pocket door system

To properly calculate the sizes of a sliding pocket door system, it is first necessary to understand the difference between "door opening" (or passage size) and "maximum overall dimensions".

The door opening, or passage size, refers to the actual dimensions in height and width between the jambs (if present) and from the level of the finished floor to the top beam. A standard sliding pocket door has the same sizes of a corresponding hinged door. It typically measures 30" or 36" in width and 80" in height. It is also possible to build customized solutions for very large or very small passage sizes. The dimensions for single-leaf doors start from a width of 24" up to 48", and from a height of 80" up to 120".

The maximum overall dimensions refers instead to the total space required to install a sliding pocket door system. In width, this size is given by the sum of the passage size and the pocket dimensions while in height it is given by the length from the finished floor level to the upper edge of the architrave.

While in a new construction you typically have the freedom to choose the door size you want, in renovation projects you may find some constraints and the overall dimensions is the obligatory starting point to choose the size of your door.

Types of counterframes for sliding pocket doors

Choosing the correct counterframe model is not difficult, but certain key factors must be taken into account. These include the type of door and the type of opening.

- Type of door: is the door going to be fitted with jambs or not (the so-called flush-to-the-wall doors).

The jambs and architraves refer to all those elements that cover the wall edges around the doorway. In traditional doors, they normally protrudes from the door and the walls around the door panel. If instead there is no edgings, we refer to modern doors without jambs and architraves flush-to-the-wall. Each of these solutions requires a specific counterframe.

Systems for sliding doors with jambs

The evergreen classic

Space-saving solutions or extra-large openings. For the bathroom or the living room.

Choose your ideal solution among the systems for traditional sliding pocket doors with jambs.

Systems without jambs and architraves

Minimalist style

Whether sliding or hinged, the door is always perfectly integrated into the wall, almost invisible.

All the solutions for flush hinged doors and sliding pocket doors without jambs and architraves.

- Type of opening: where is the sliding door going to be place?

Sliding pocket doors can be suitable for different contexts and, though they are highly appreciated for their space-saving function, they are an excellent solution to discretely separate rooms, walk-in wardrobes, storerooms and service rooms. Moreover, especially with the larger-size versions, they add a modern and design concept to the setting, transforming it into a wide open space.

Special striking solutions can be combined with sliding pocket door solutions. Some examples include curved doors or telescopic doors, which allow to create an opening up to 15 feet wide. Each of these solutions requires the installation of a dedicated sliding pocket door systems.

Also, ECLISSE offers wiring-ready counterframes that allows to use the section of the wall that hosts the pocket to install lighting points, sockets and switches.

Telescopic

sliding pocket doors

Openings up to 15 ft

With this solution, two parallel door panels can slide into the same pocket, enabling you to have an extremely large opening.

Curved

sliding pocket doors

Unleash your imagination

Have you ever thought of a curved door? This frame will allow you to have a curved sliding door, single or double.

Wiring-ready

sliding pocket systems

And there was light!

If you think that having switches, lights and sockets on the same wall where the door slides is a problem, you’re wrong. ECLISSE has devised a specific frame for this purpose.

Counterframes for stud walls

In the case of stud walls, the pocket door hardware has an open structure similar to a metal framework on which the actual plasterboard slabs will be installed.

The unassembled frame version (KIT) for stud wall has compact overall dimensions that facilitate both its transportation and handling and optimise its storage in warehouses (over 50 pieces fit into just one square meter). Moreover, it allows to decide on-site which internal passage to use (2-3/8" and 4-3/8") according to the finished wall thickness, since the structure thickness can be widen during the installation phase. Thanks to the innovative interlocking assembly system, no screws or screwdrivers are required, making the frame assembly easy and quick.

The open structure is 20% more resistant to lateral bending compared to equivalent products currently available on the market*.

The reinforced vertical bars, together with the horizontal bars, result in a far sturdier structure compared to frames made of a single metal sheet, normally found in closed structures.

* Based on internal laboratory tests conducted on various equivalent counterframes.

10 predrilled reinforcing horizontal bars

- Patented No. US 11,499,309 / 11,761,202 -

Made from 0.7 mm thick galvanized sheet steel sections with an inverted swallowtail-shaped profile for improved resistance to pressure. And predrilled for attaching the plasterboard sheets more easily.

Metal header

Improves resistance to any pressure coming from above.

Vertical reinforced bars

They are made from galvanized steel with a double reinforcement fold for high resistance to bending.